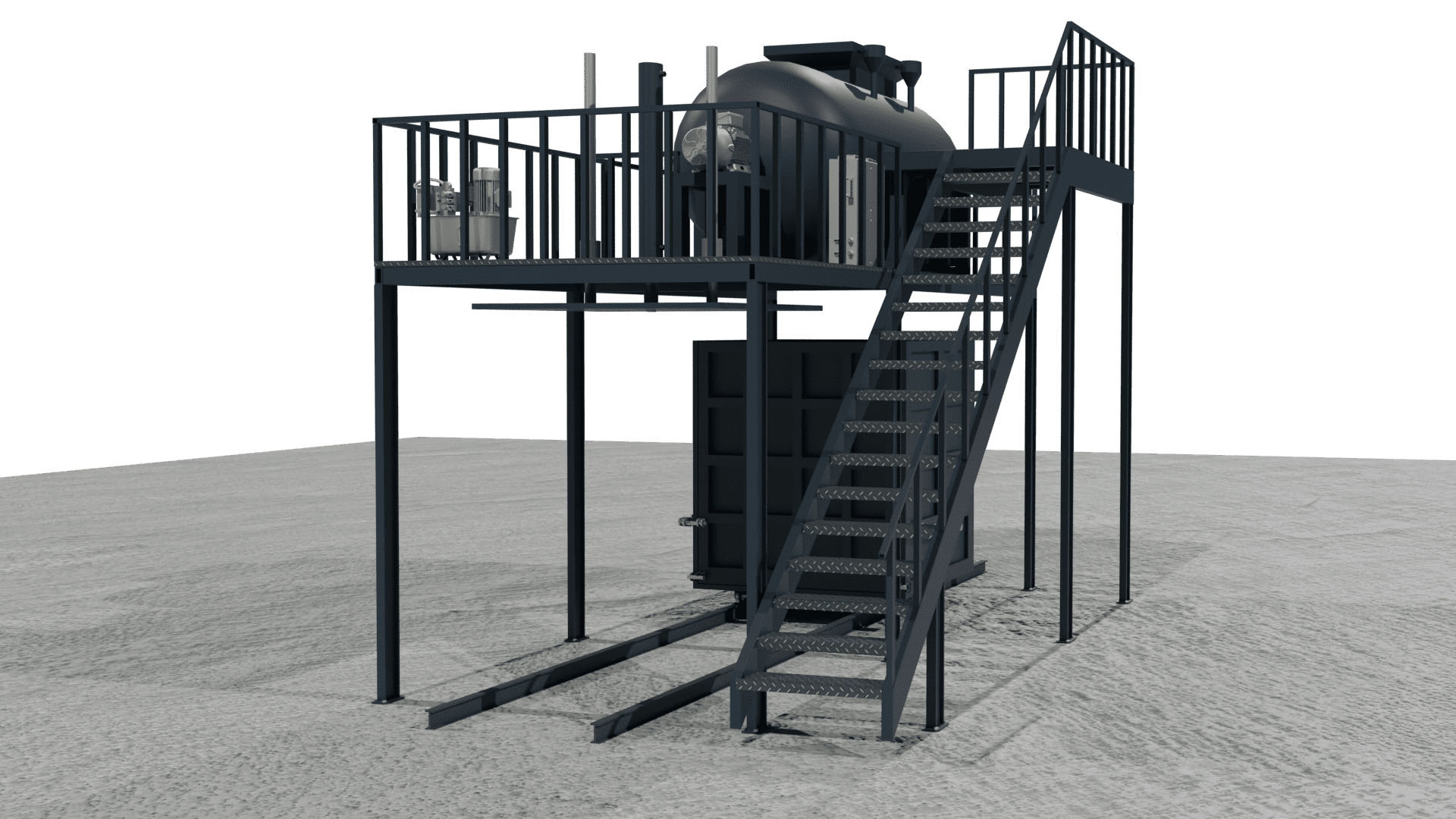

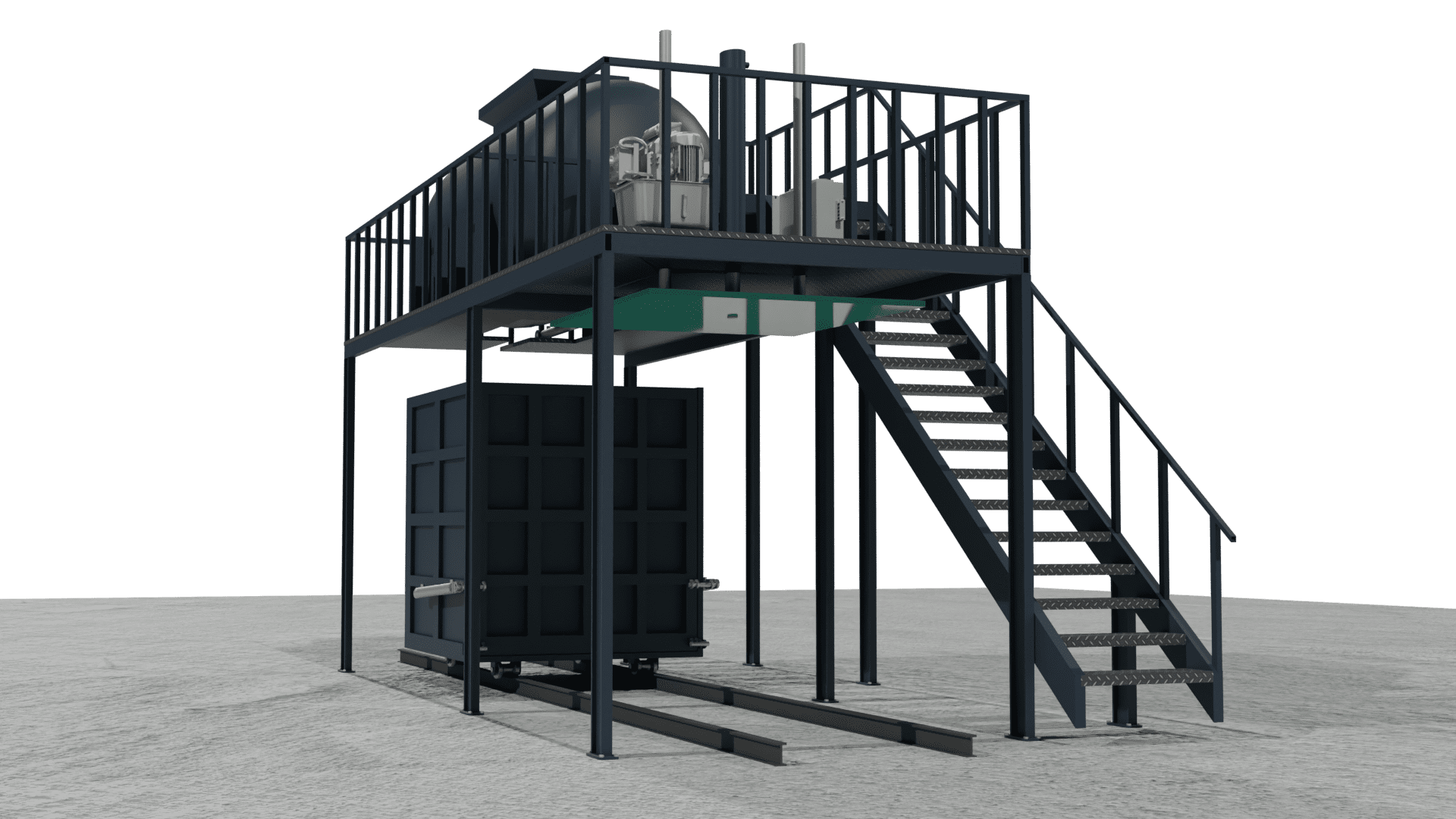

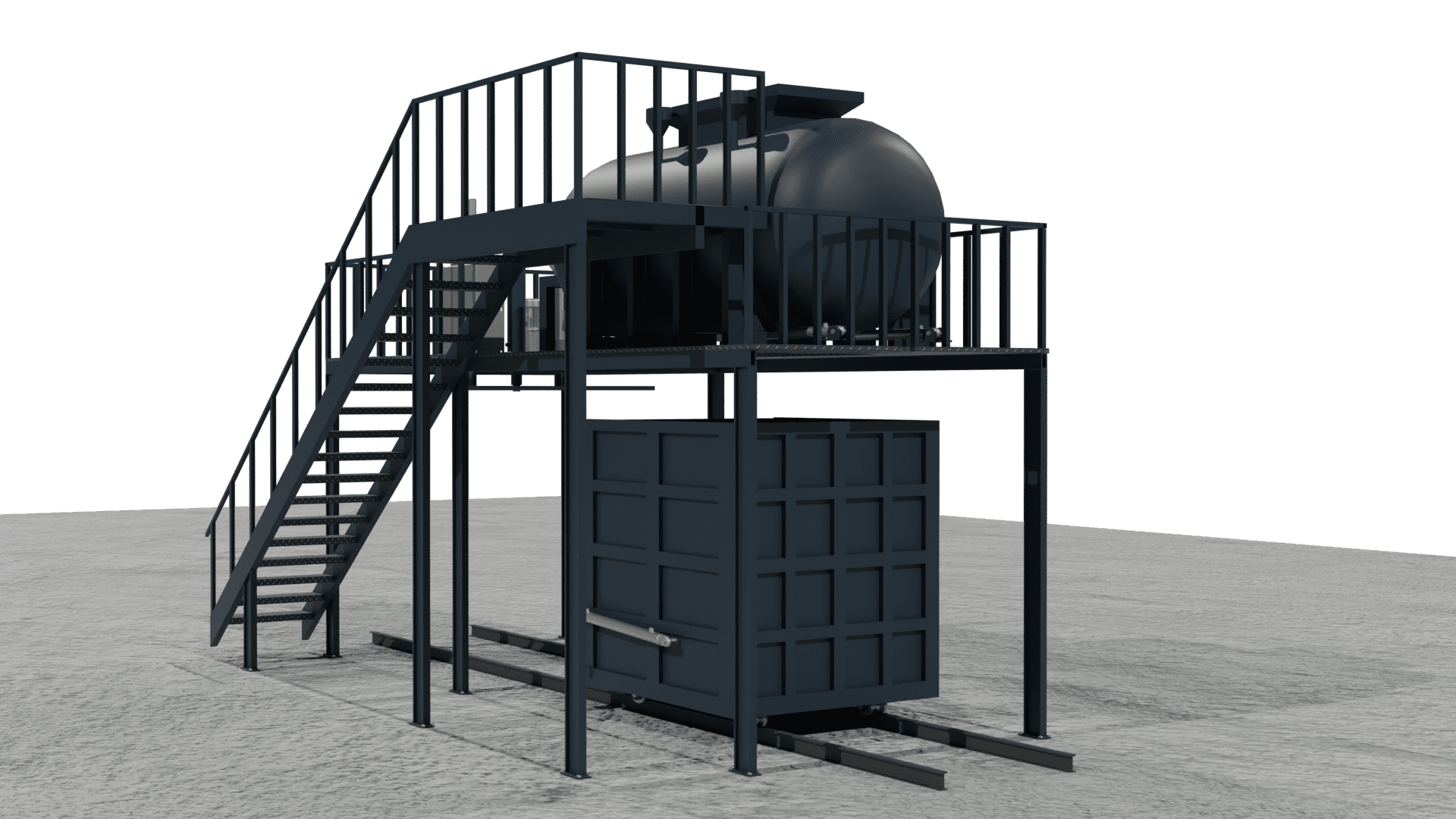

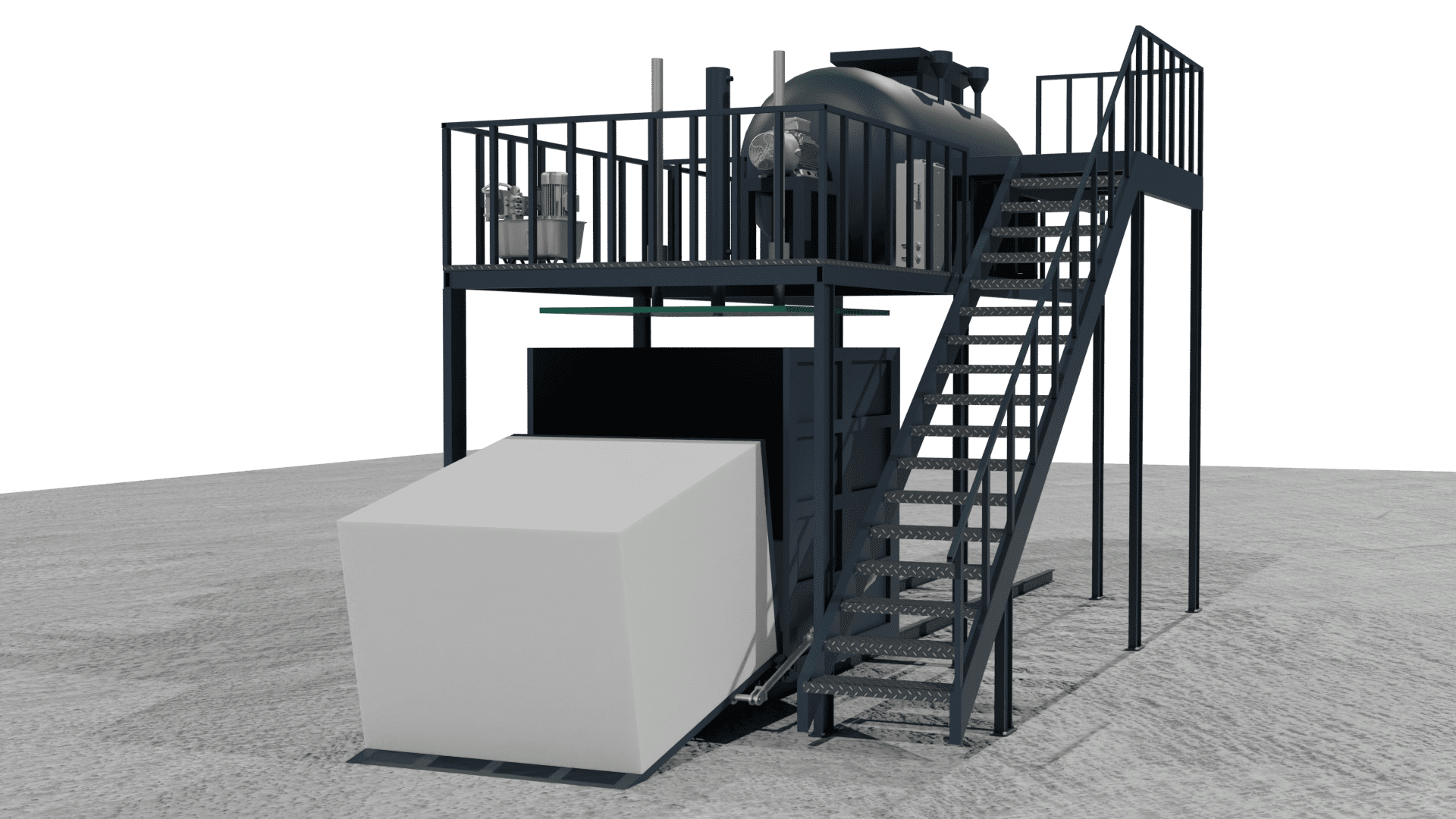

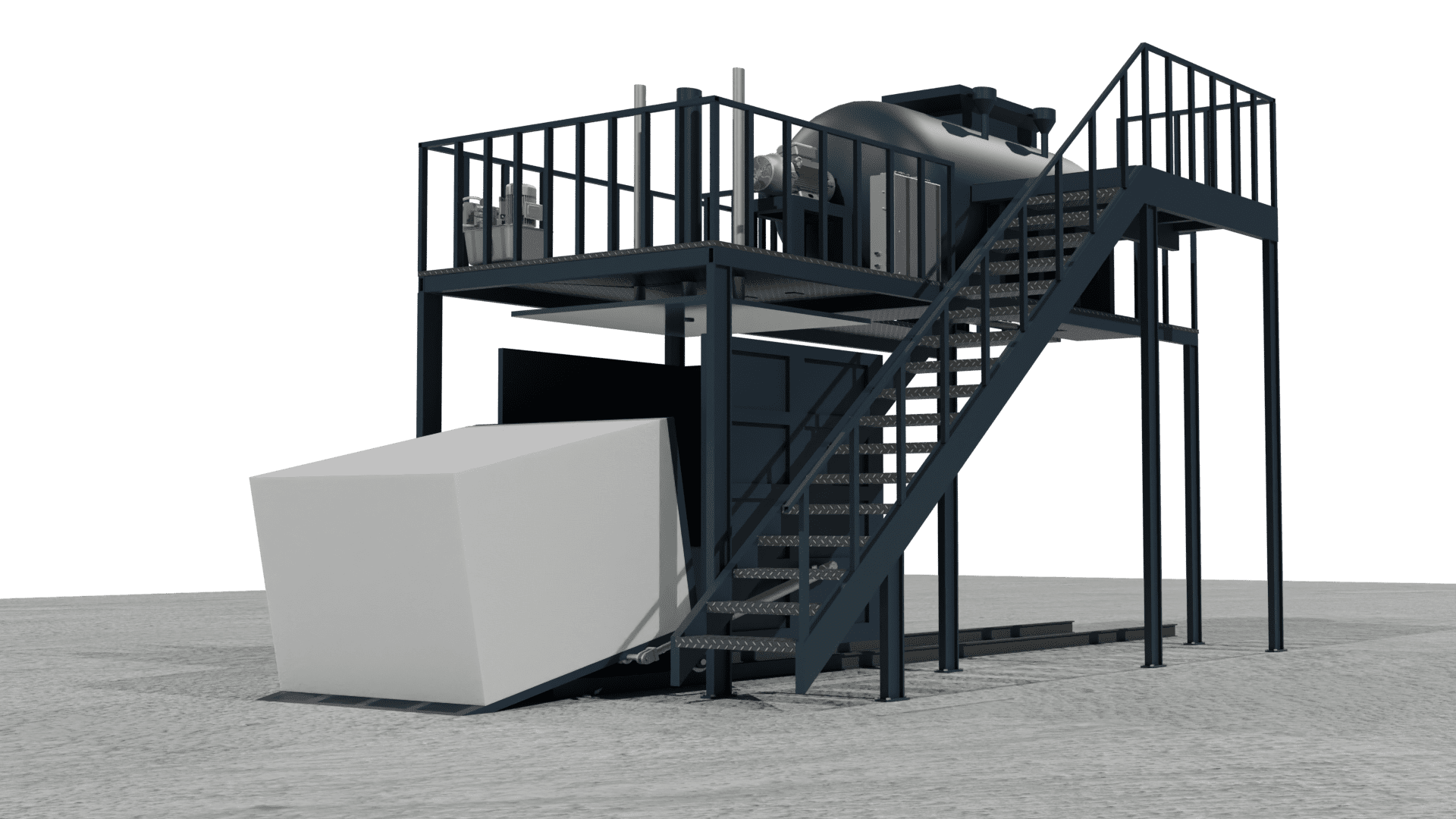

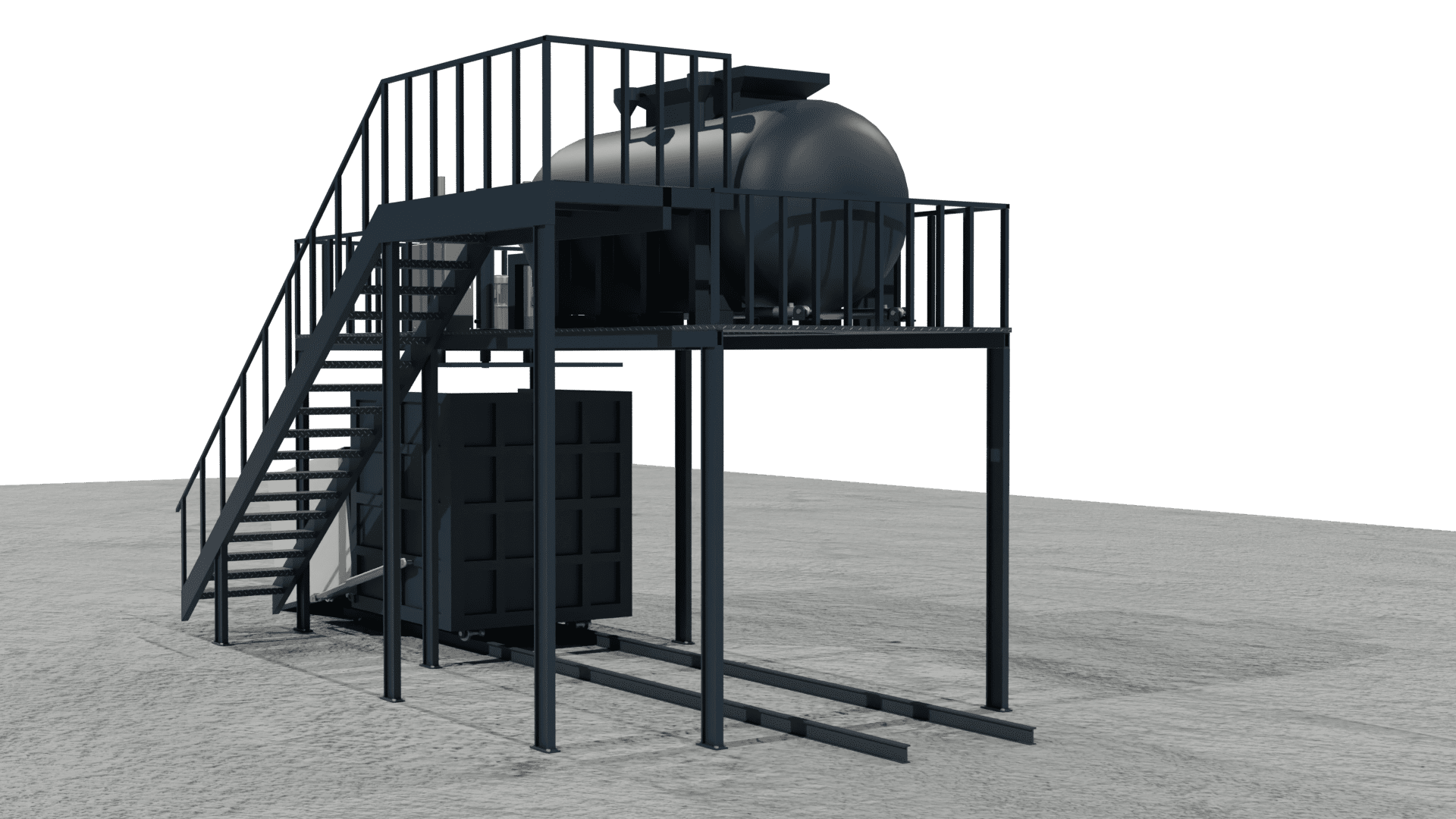

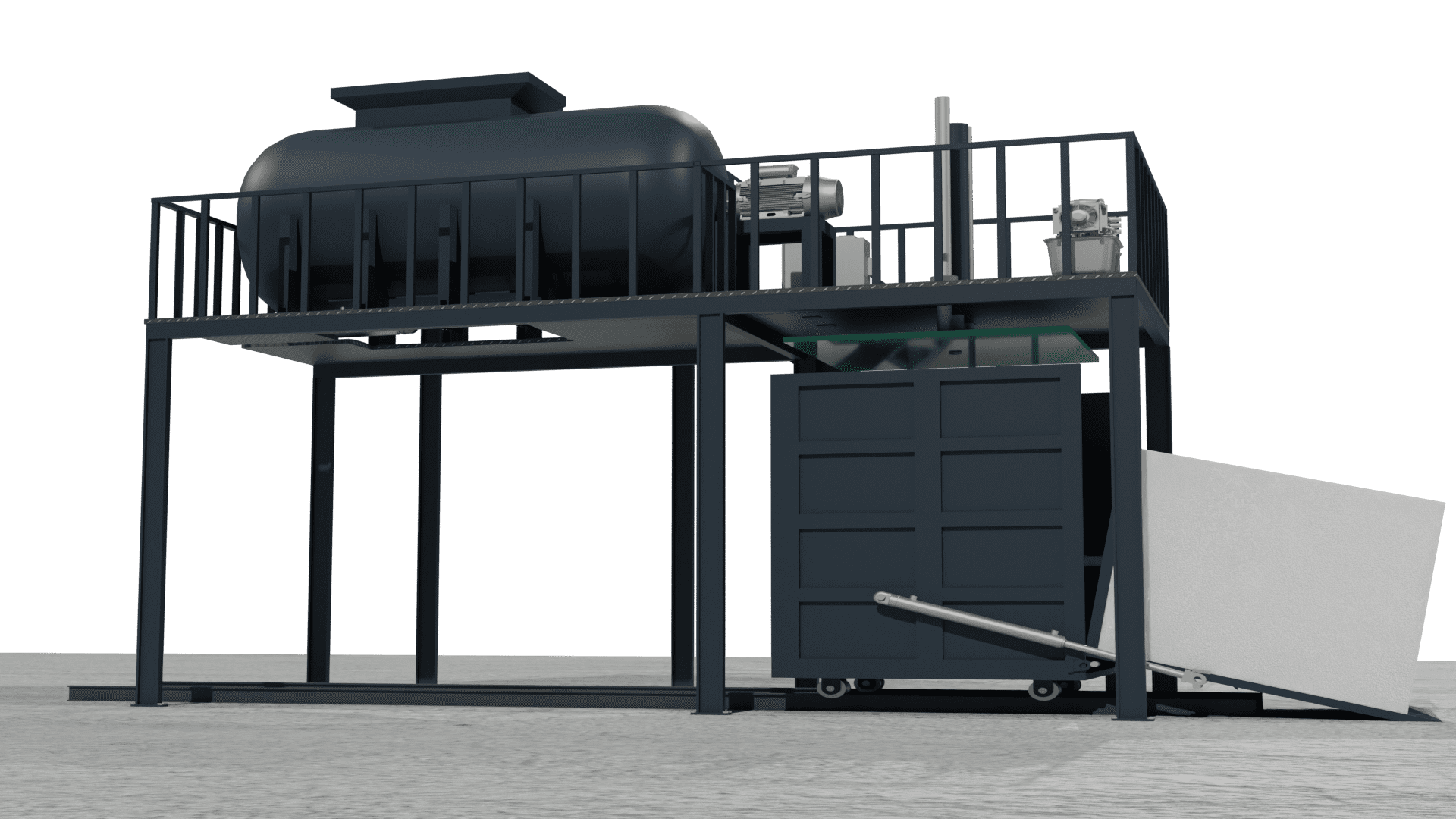

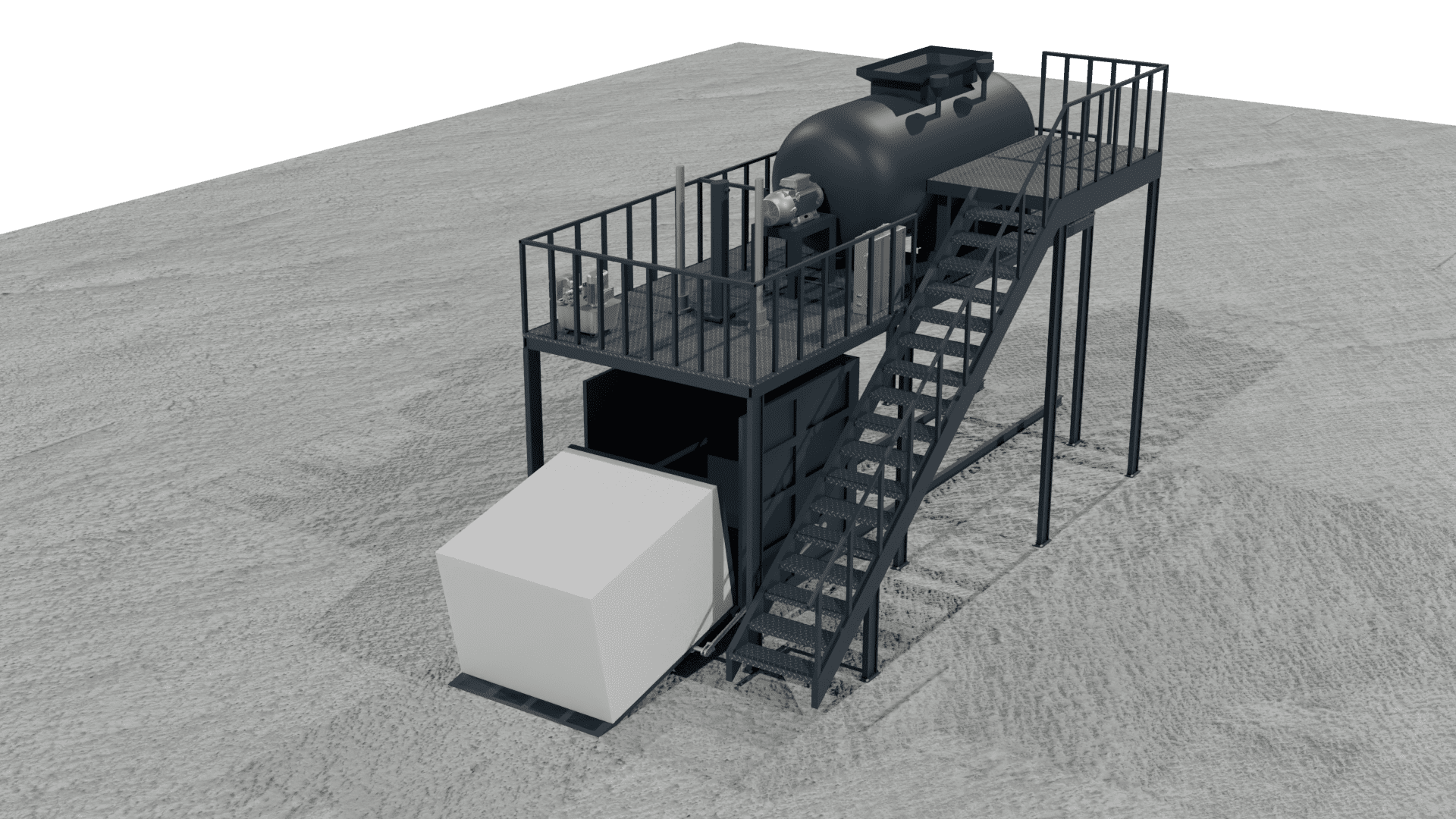

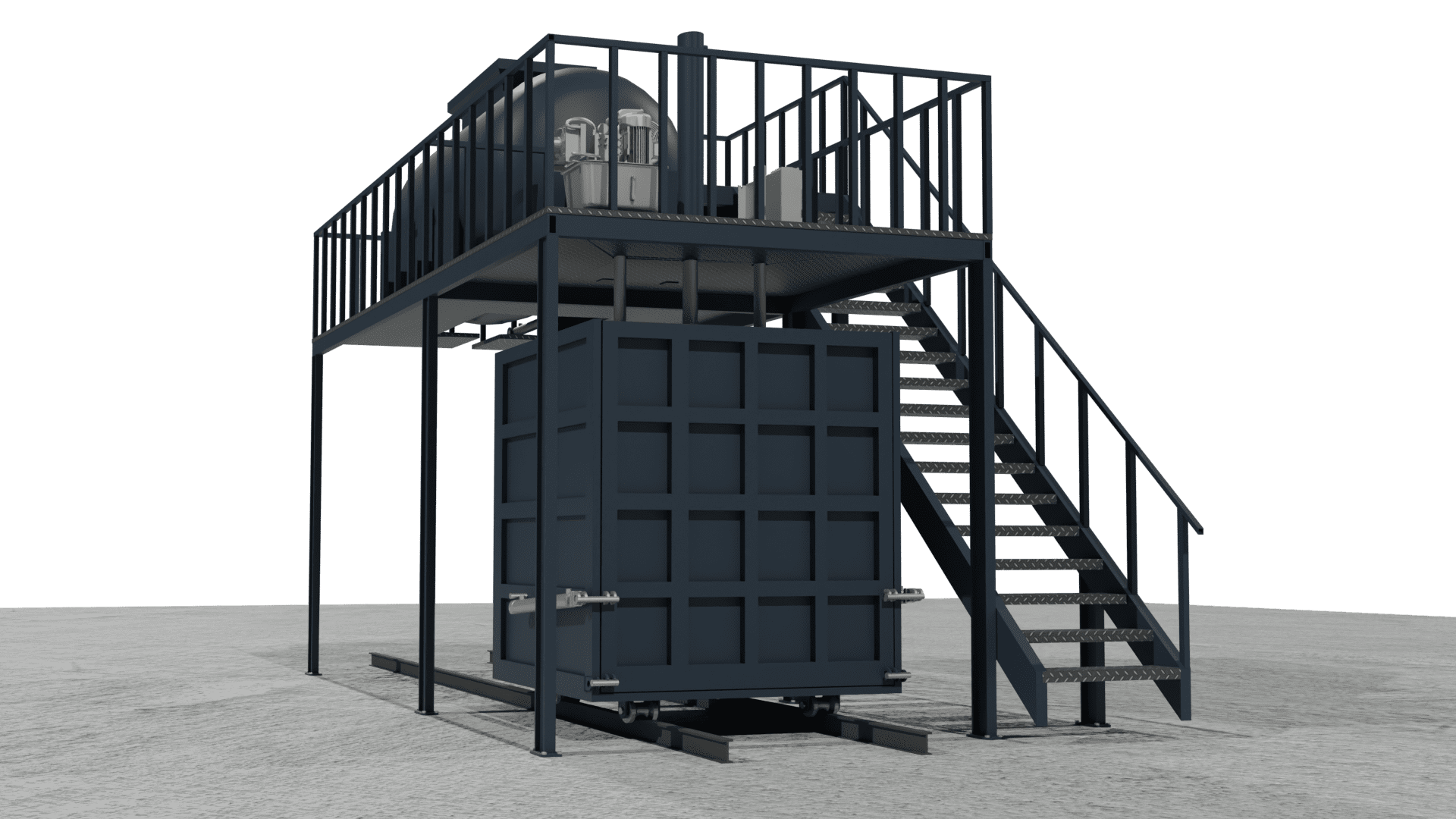

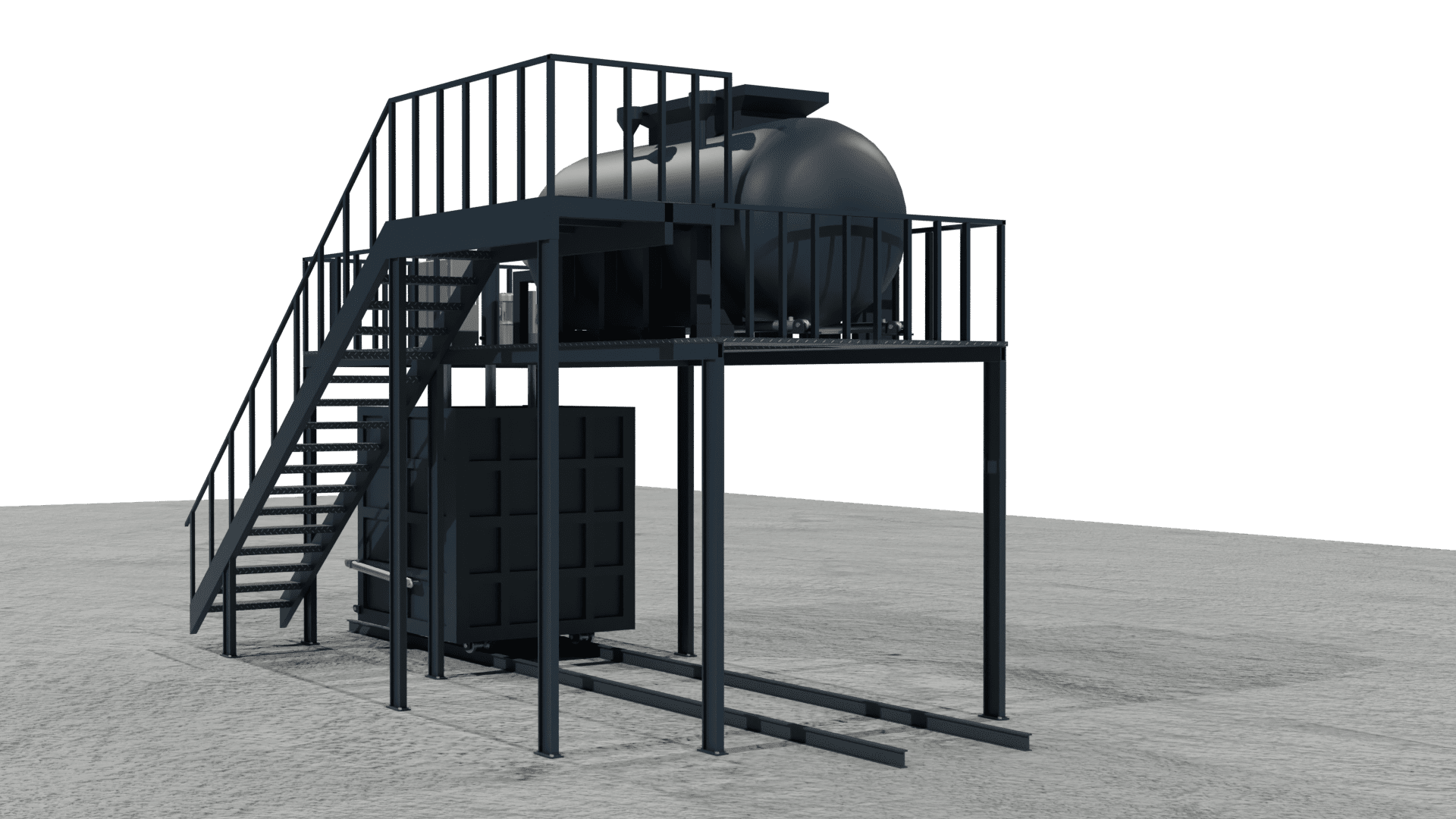

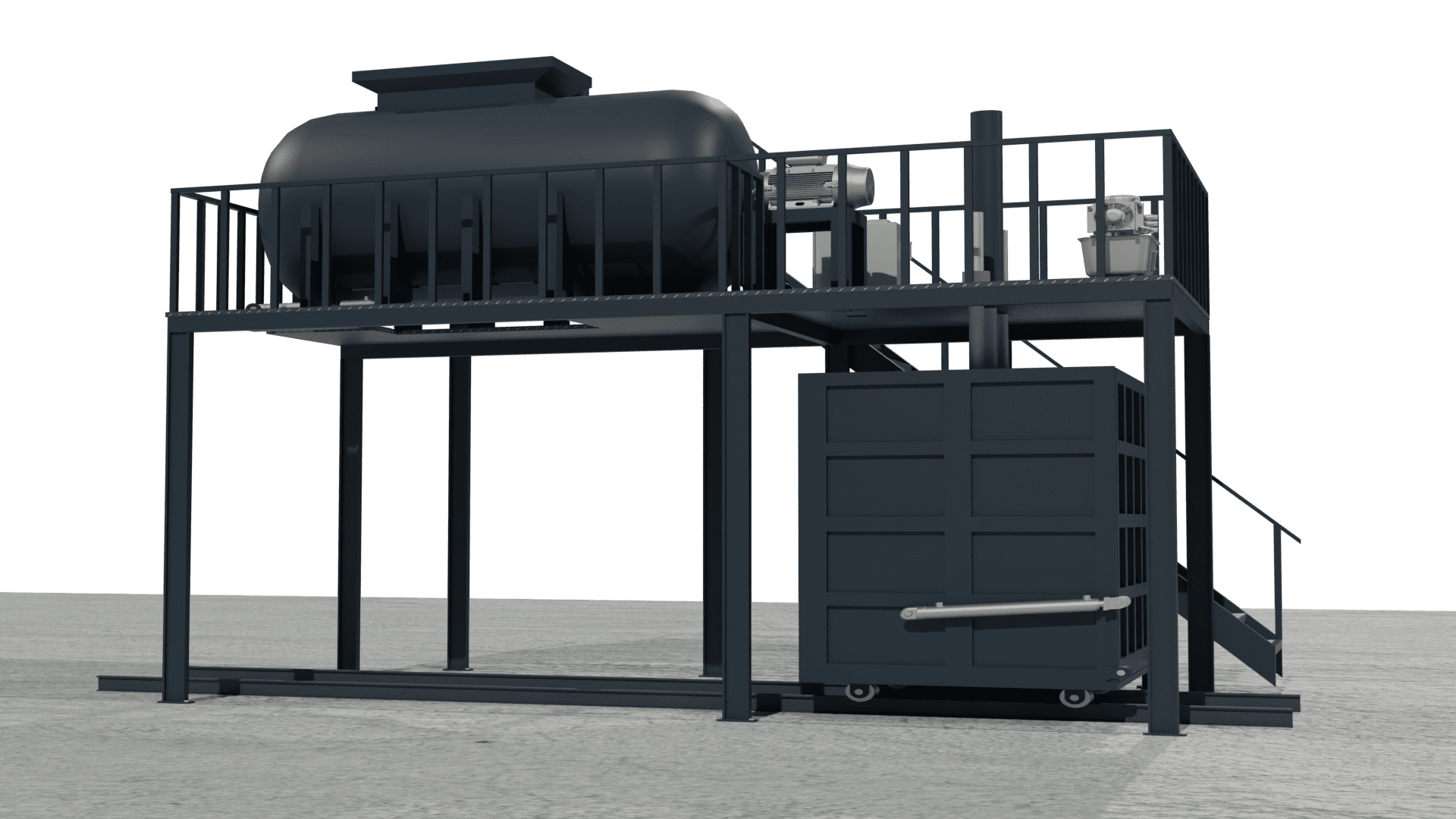

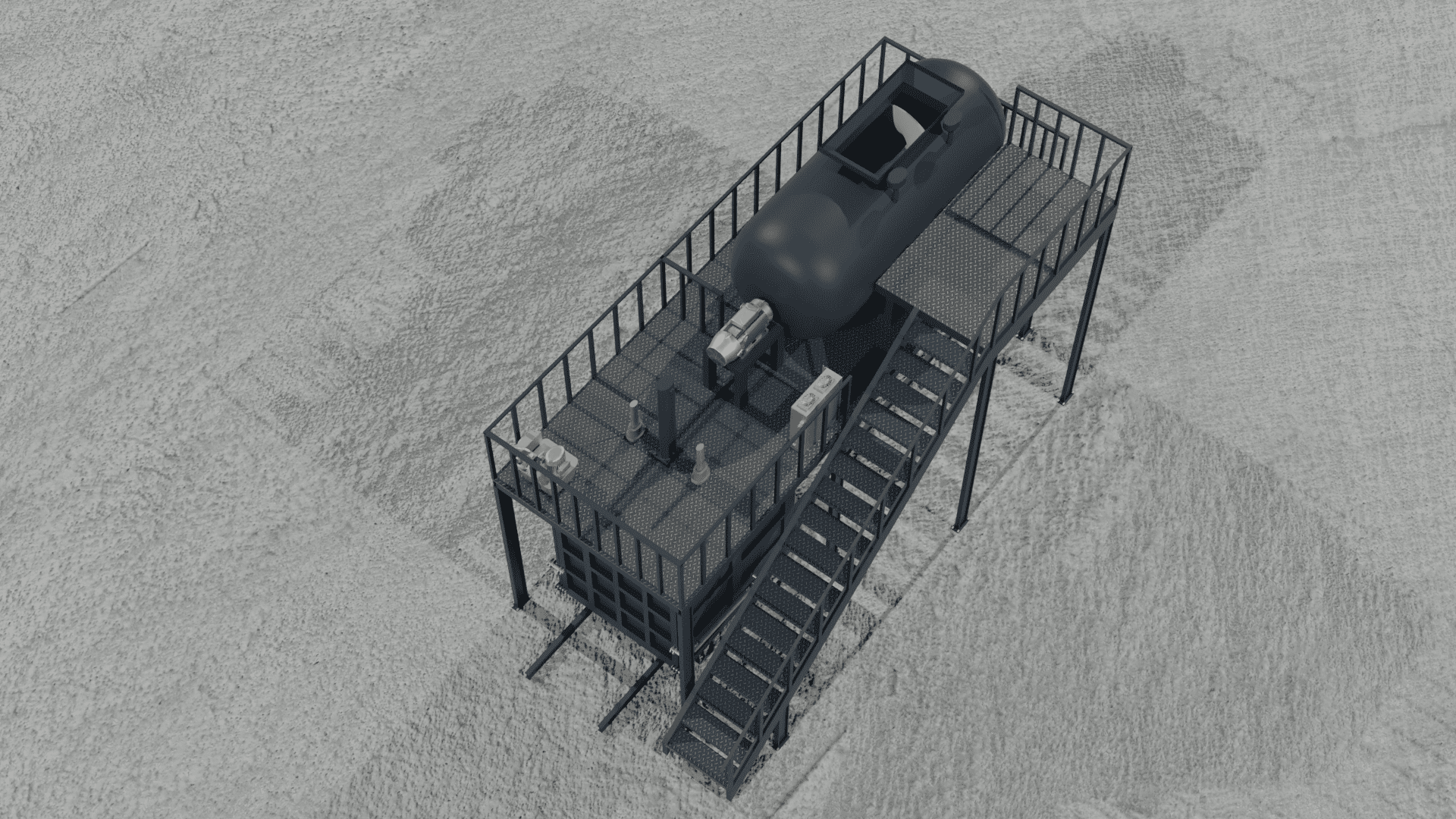

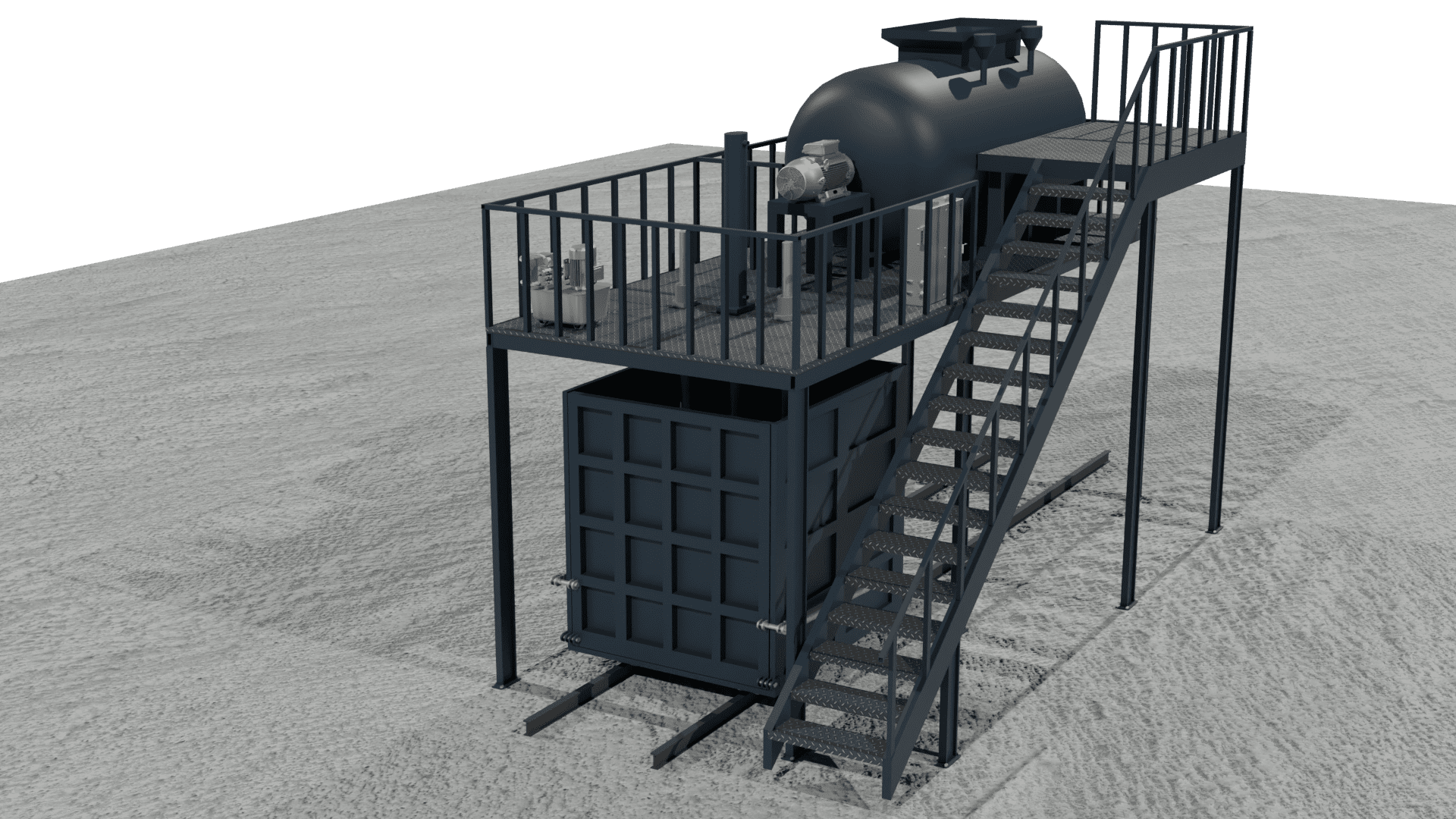

MK-1050 Foam Granule Bondex Casting Machine

What does it do?

This machine, named MK-1050 Foam Granule Bondex Casting Machine, is an industrial equipment used to produce high density materials formed by combining foam granules and binder material. These materials are used in various industries, such as building materials in the construction industry, protective packaging materials in the packaging industry and sound insulation in the automotive industry.

This machine allows the material to be shaped by mixing foam granules and binder material in a predetermined ratio and then placing them in a mold. As a result of this process, high-performance, high-density and durable materials can be produced.

How is it used?

The Foam Granule Bondex Casting Machine is used by following a process procedure that usually includes the following steps:

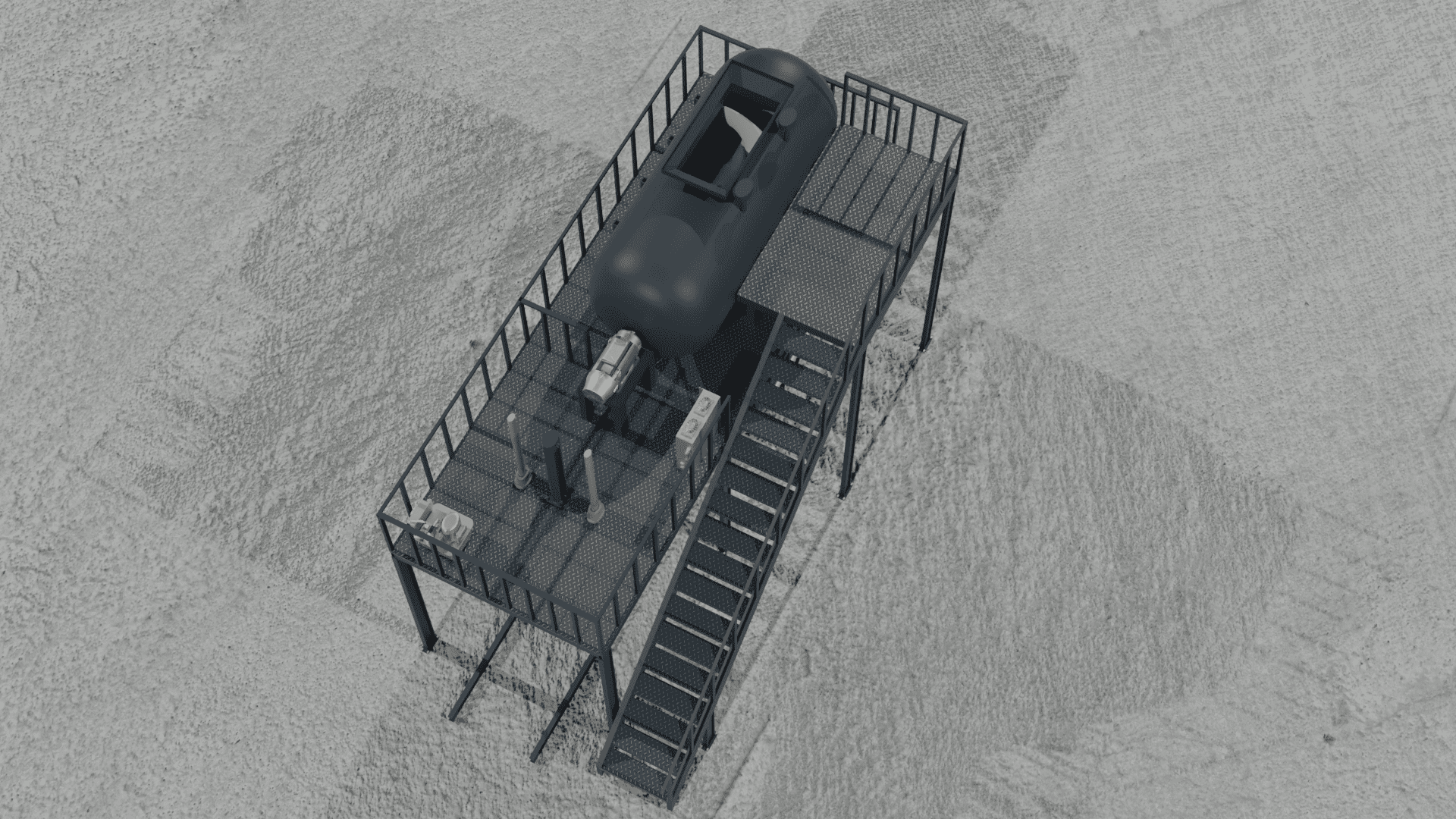

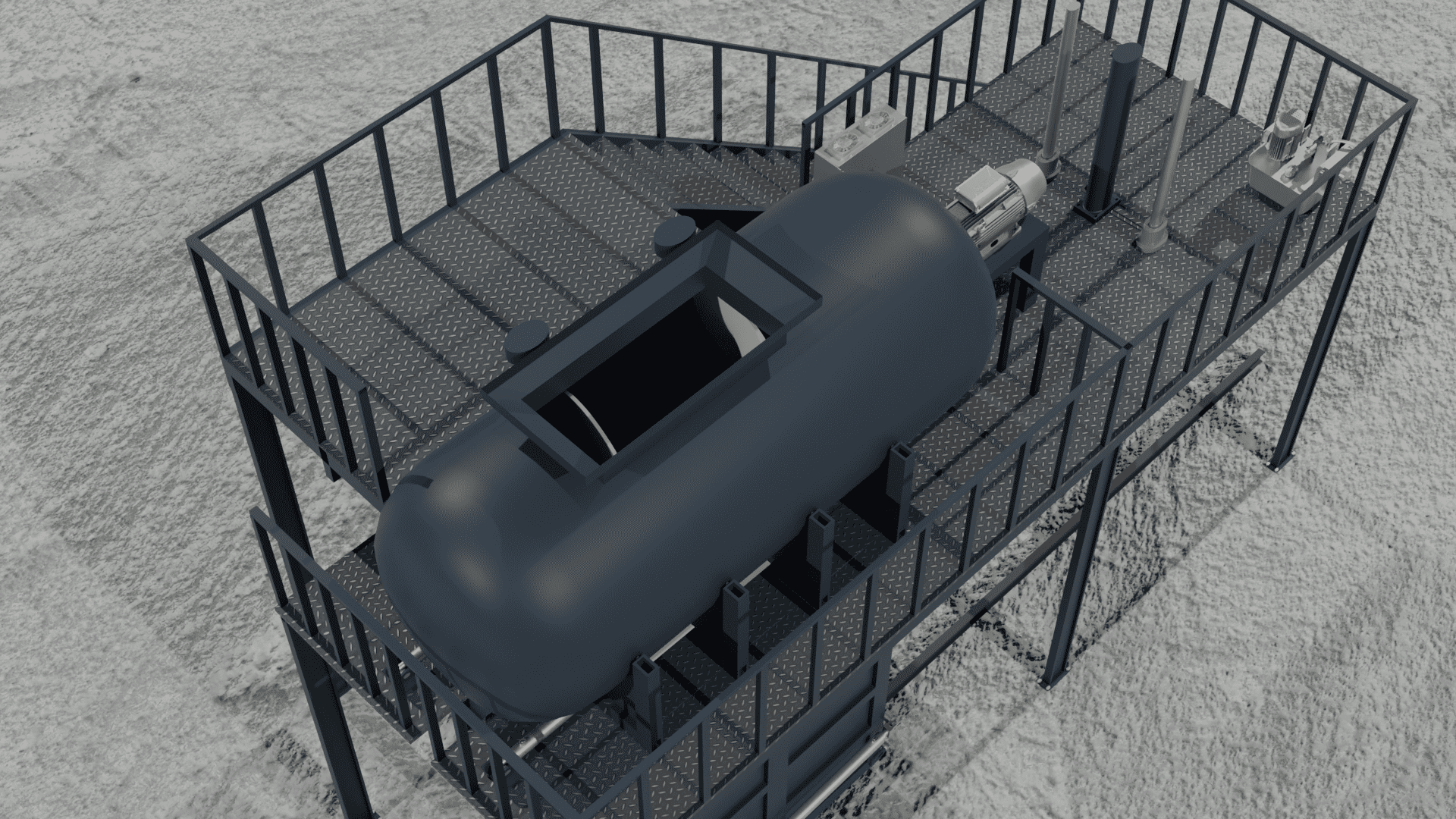

- Preparation: First, the foam granules and binder materials are prepared in the correct proportions and filled into the hopper of the machine.

- Mixing: The machine mixes the materials in the hopper to obtain a homogeneous mixture.

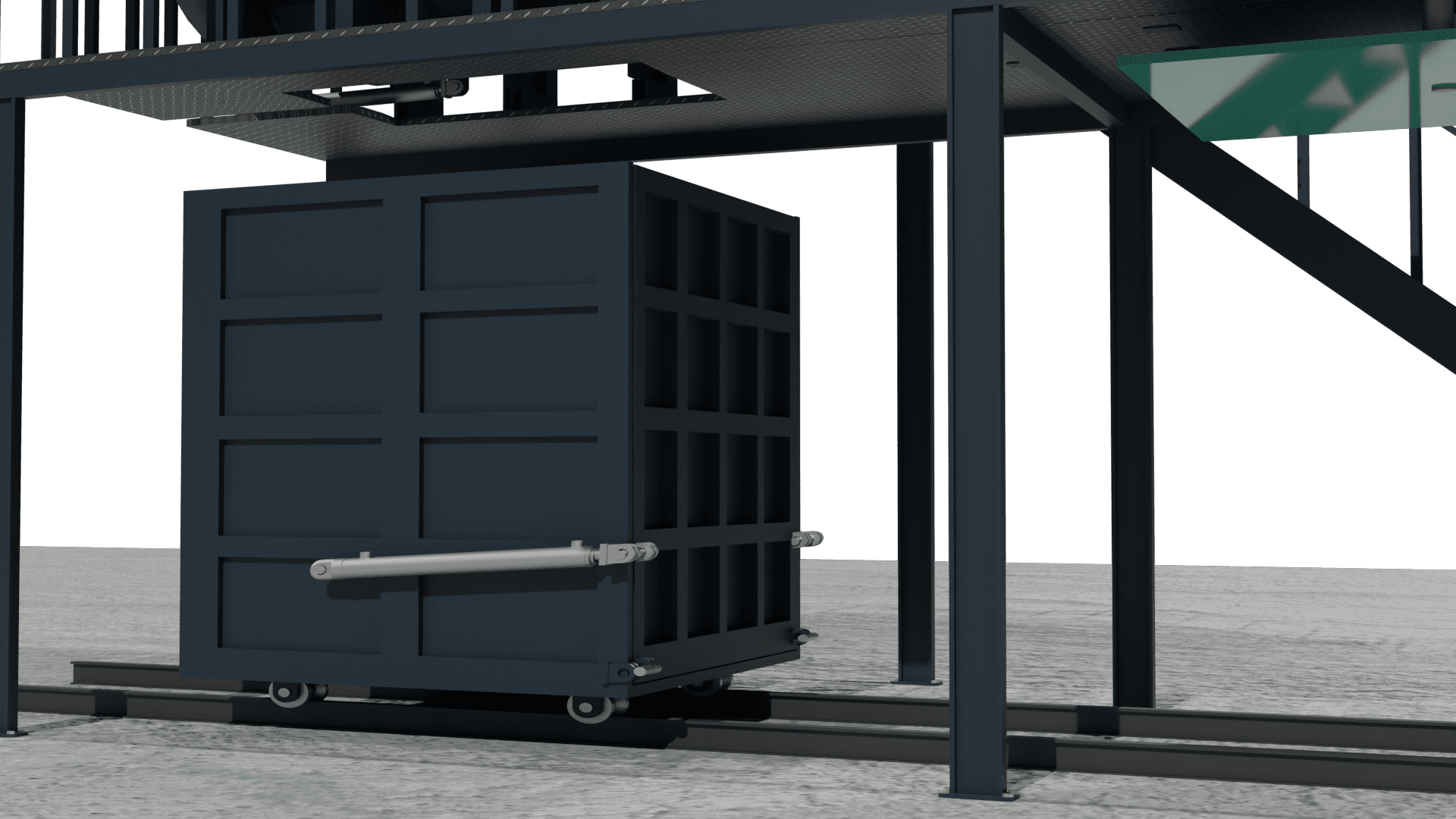

- Forming: The mixture is then formed into the desired shape by filling the machine into a mold.

- Hardening: The material in the mold hardens for a set period of time and is finally removed from the mold.

During this process, operators adjust the speed, pressure and other parameters of the machine using the necessary controls to operate the machine. The process produces high-performance, lightweight and durable building materials.

Technical Specifications

Production is made in special sizes you want.

High density production capacity is possible, please provide information for the densities you want to produce.

Benefits Provided

- Efficient production: This machine ensures a high efficiency in the production of foam products. Thanks to high-speed production, it saves time and labor in the production of foam products.

- Recycling: Our machine can also be used to recycle foam waste. This allows our customers to recycle at a higher capacity.

- Flexibility: Foam Granule Bondex Casting Machine has the capacity to produce foam products in different sizes and shapes. Manufacturers can produce customized foam products according to the demands of their customers.

- Quality control: This machine ensures a continuous quality control during the production process. The machine guarantees homogeneous distribution of the foam material and ensures high quality foam products.

- Less waste: This machine allows the economical use of foam material and minimizes waste. This makes the production process more environmentally friendly.

- Less human intervention: Foam Granule Bondex Casting Machine requires less human intervention as it is an automated system. This reduces labor costs and minimizes the possibility of human error.

- Fire resistance: This machine is designed in accordance with the standards required to ensure the fire resistance of foam products. This is important for the safety of customers

Application Areas

- Furniture industry: This machine is used to produce foam for sofa, mattress, cushion, chair and other furniture products.

- Automotive industry: This machine is used to produce foam for seat cushion, car upholstery, steering wheel, seat cushion and other parts for automotive industry.

- Footwear industry: This machine is used to produce insoles, inner lining and other foam products for the footwear industry.

- Insulation industry: This machine is used to produce foam for insulation materials. These materials are used to provide sound insulation, thermal insulation and waterproofing for buildings and other structures.

- Packaging industry: This machine is used to produce foam for packaging materials. These foam materials are used for the safe transportation of sensitive electronic devices and other fragile products.

- Healthcare industry: This machine is used to produce foams for orthopedic pillows, mattresses, prostheses and other healthcare products.