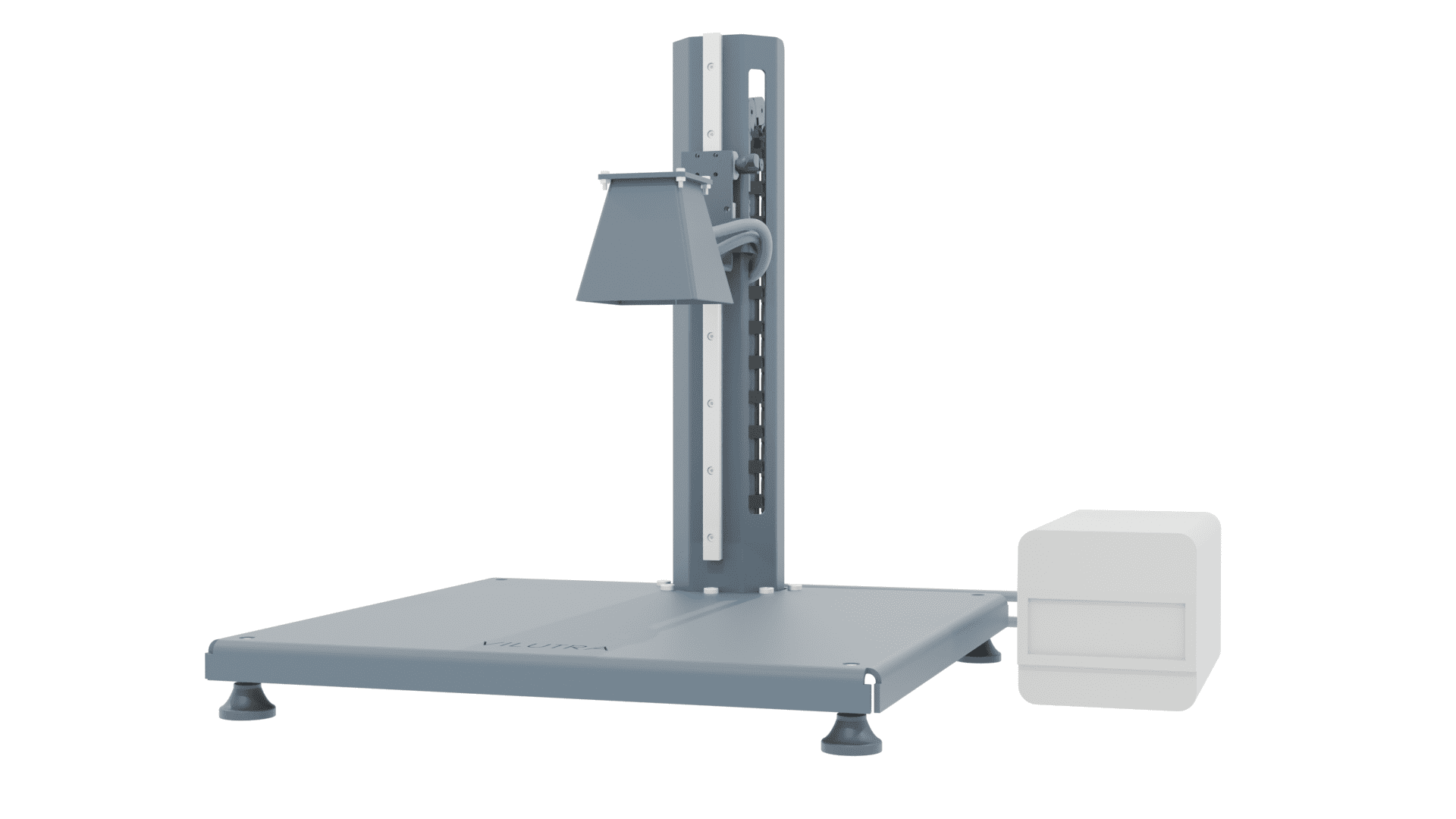

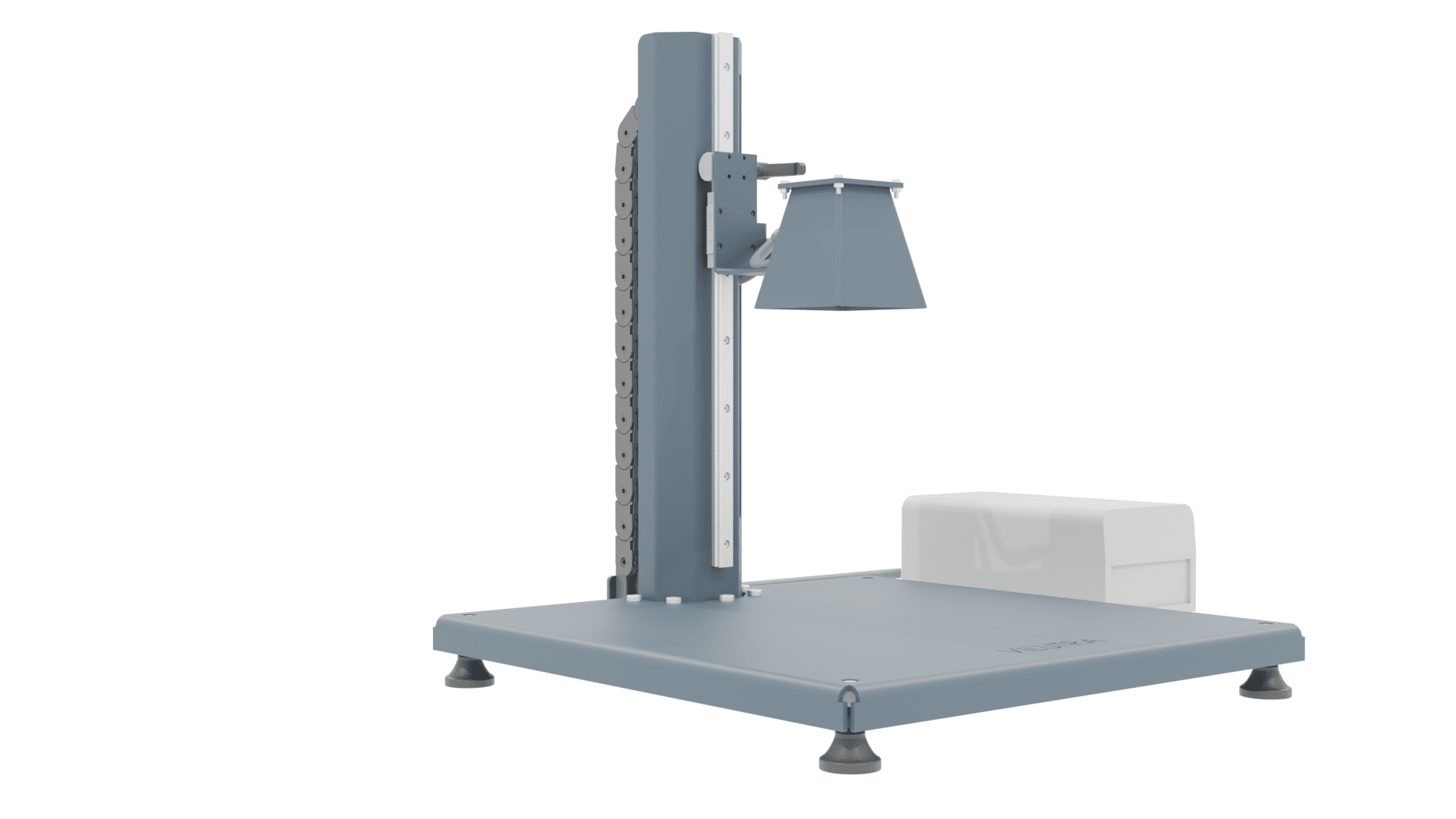

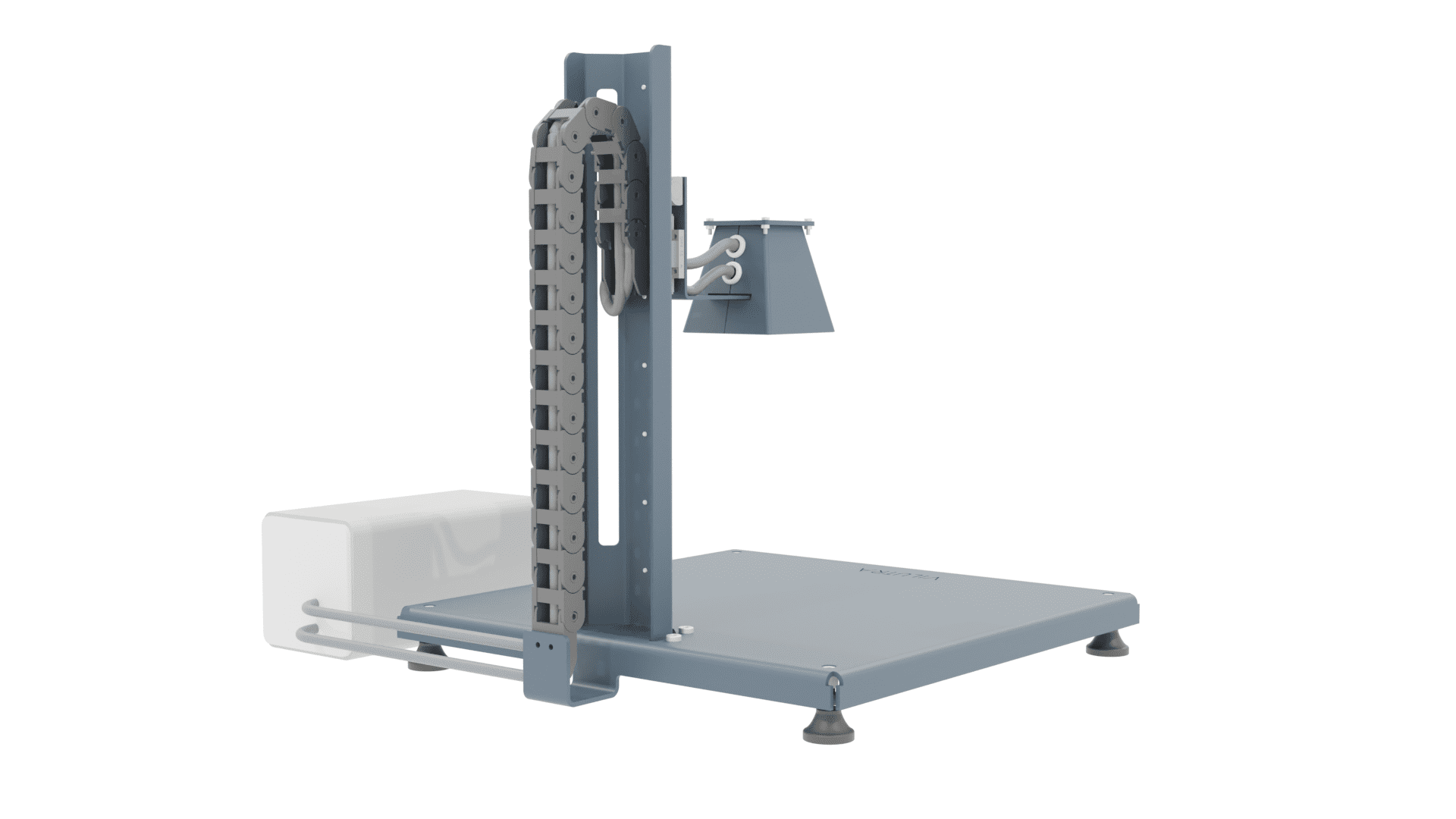

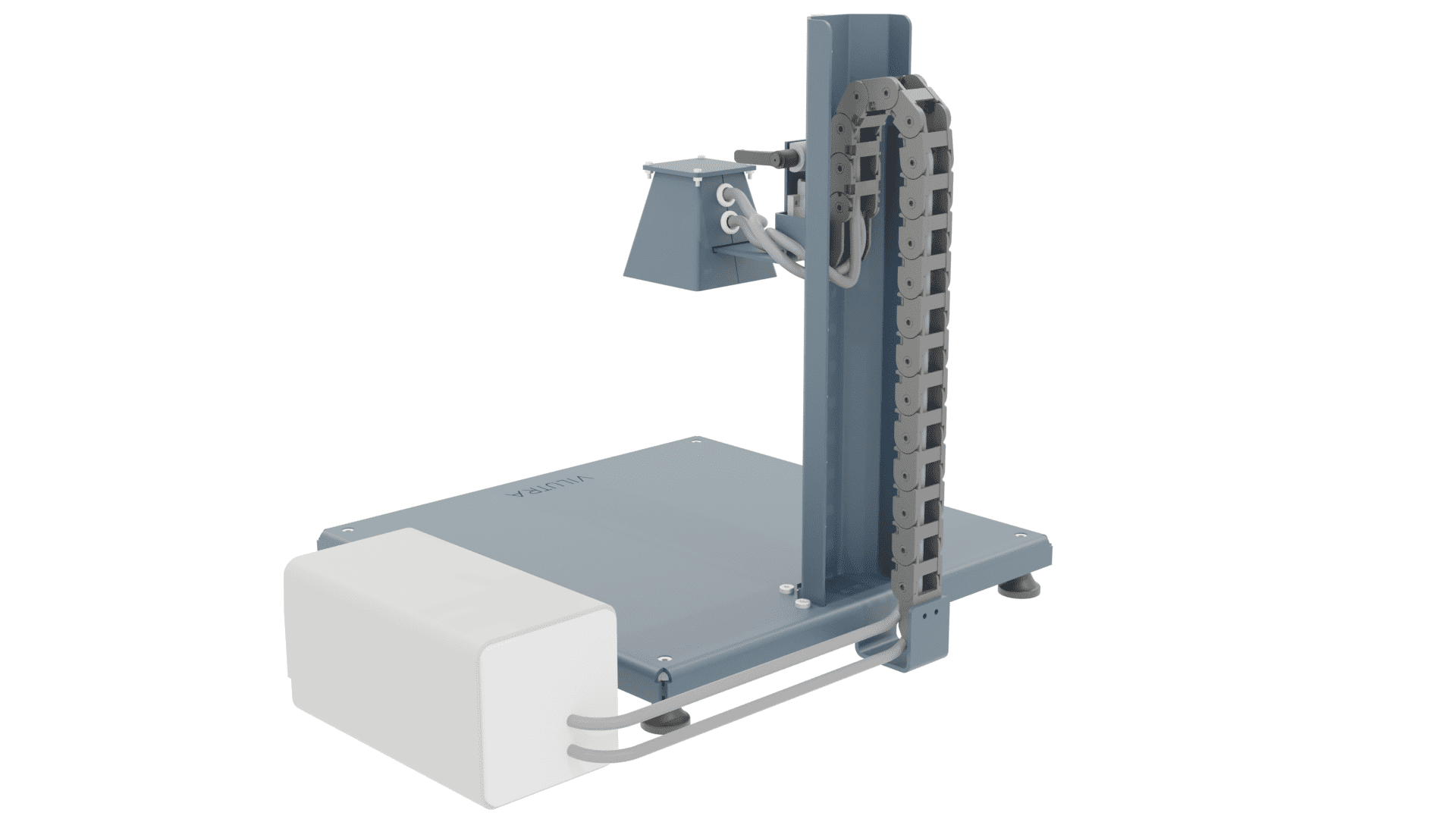

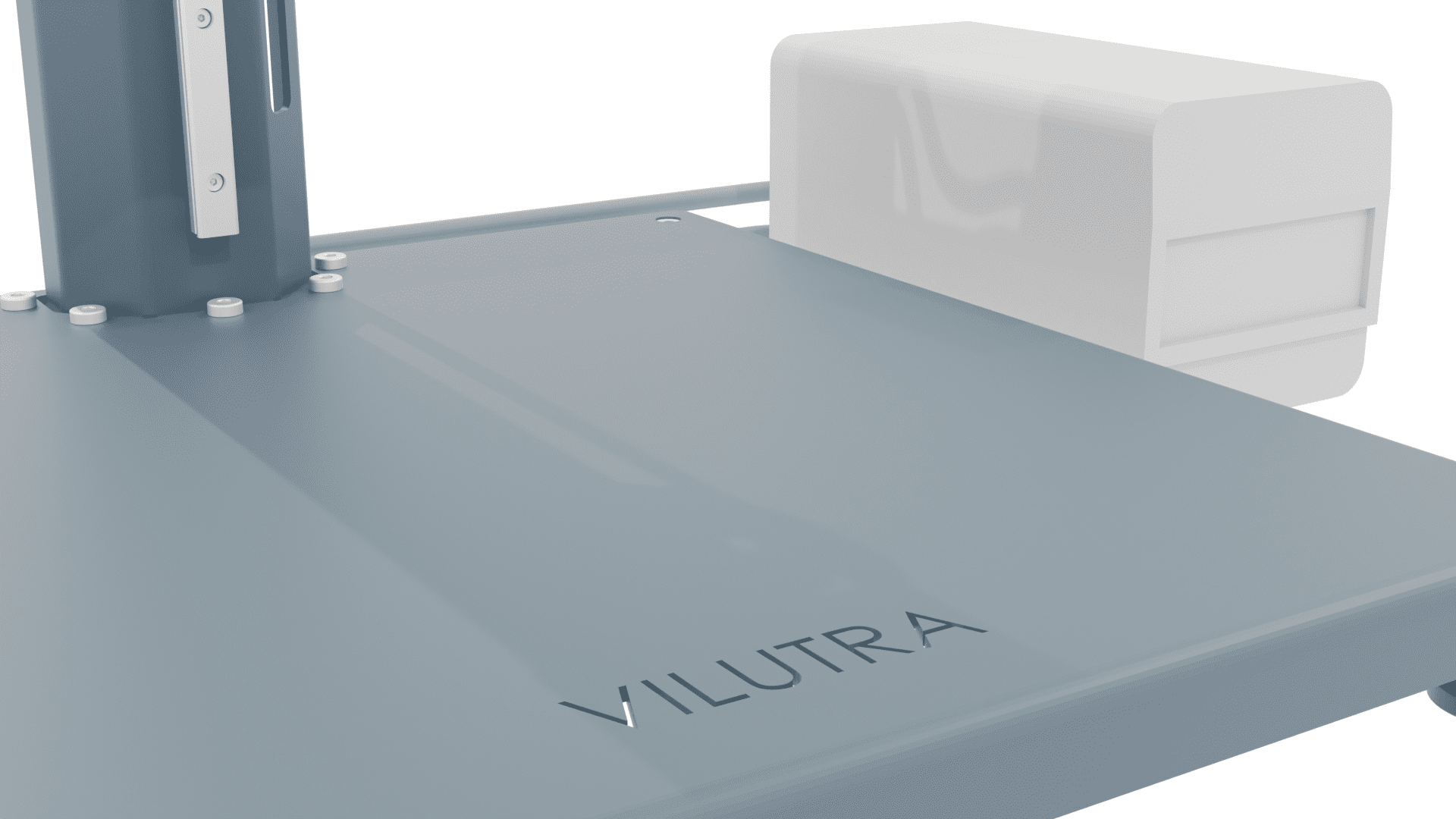

VILUTRA MK-1020 FOAM MEASUREMENT TESTER

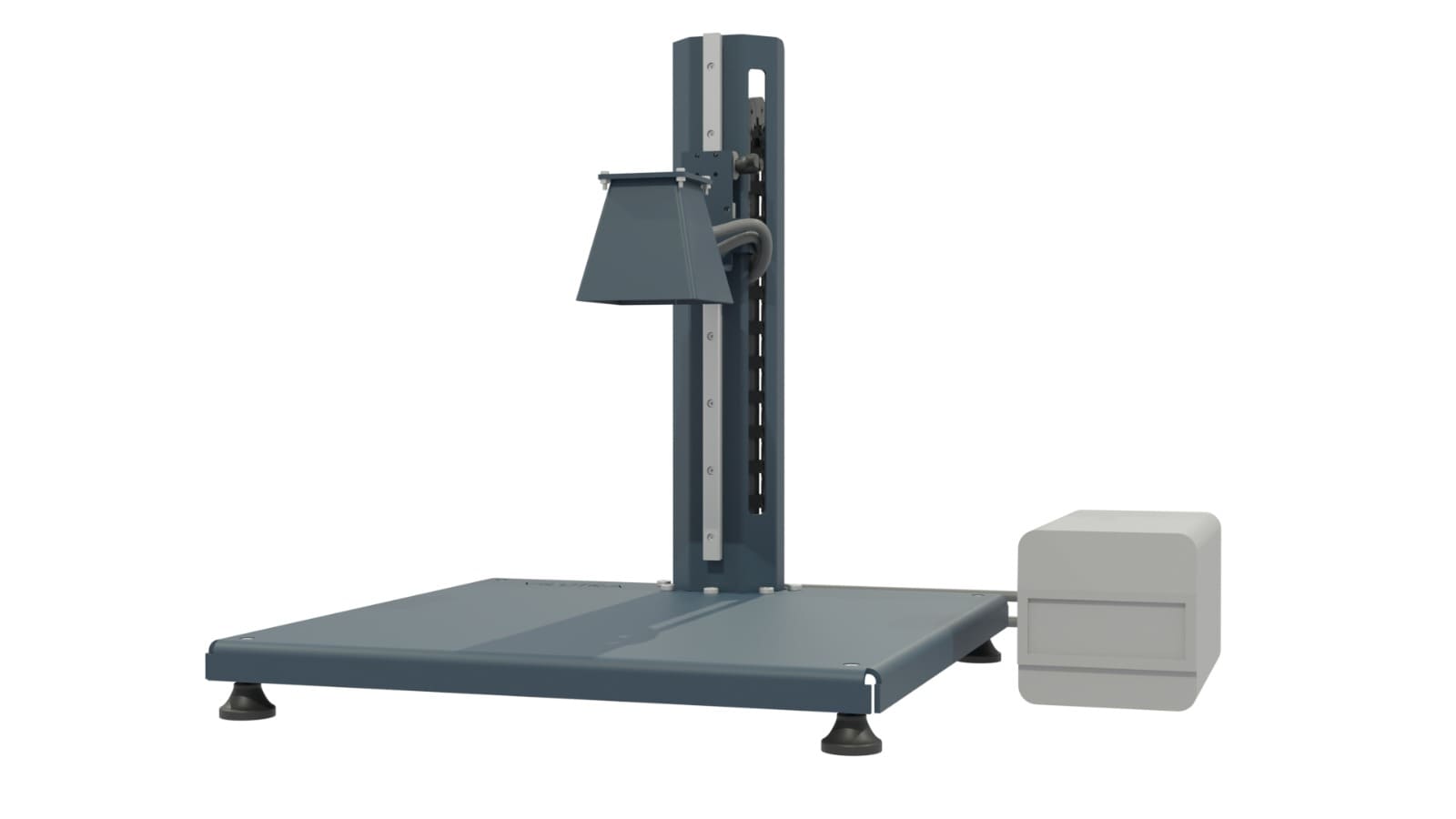

The MK-1020 Foam Measurement Tester is a device used to measure the amount of rise during the formation reaction of foam materials. It is used to determine how much the foam material rises during the mixing and reaction process.

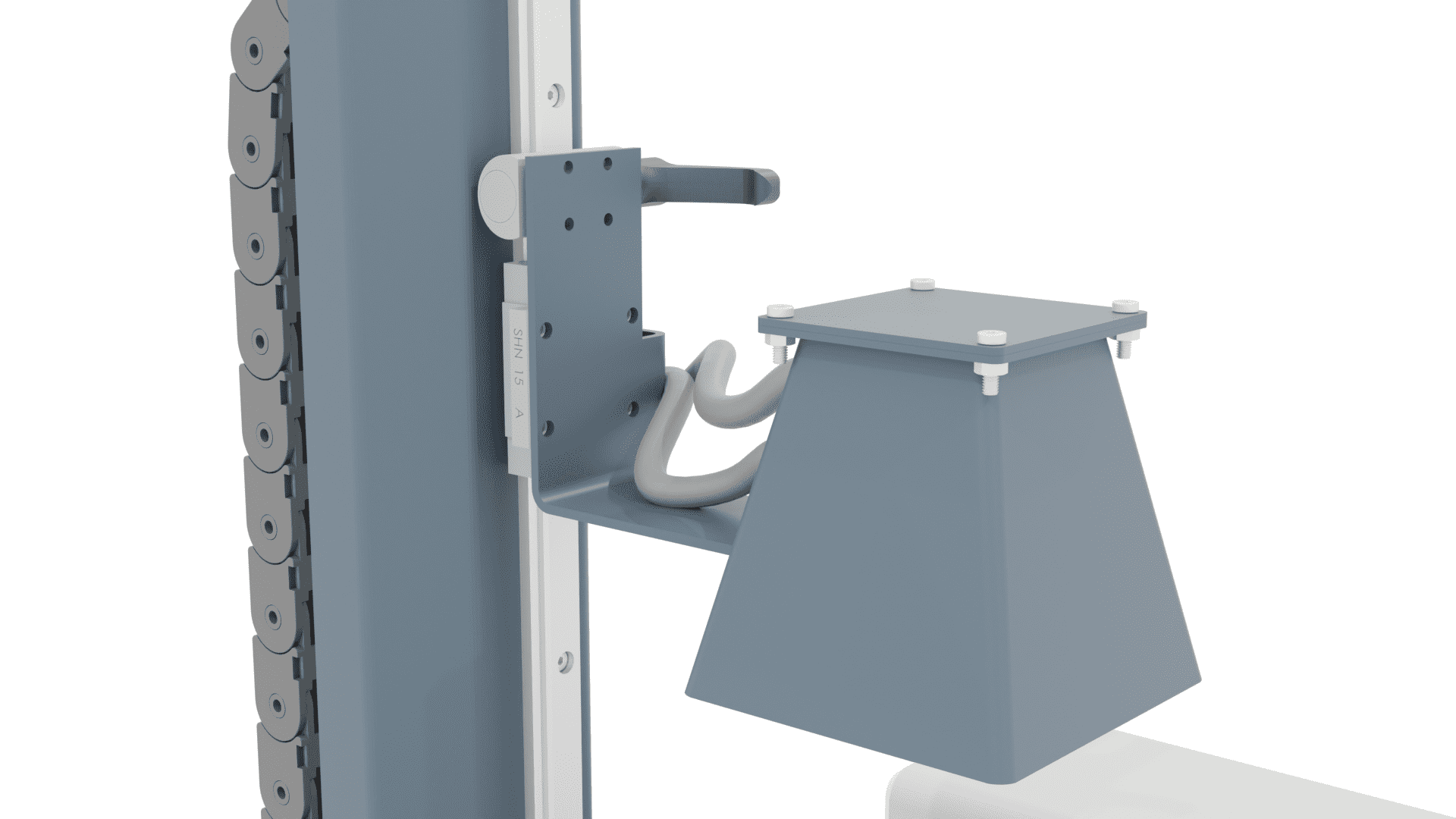

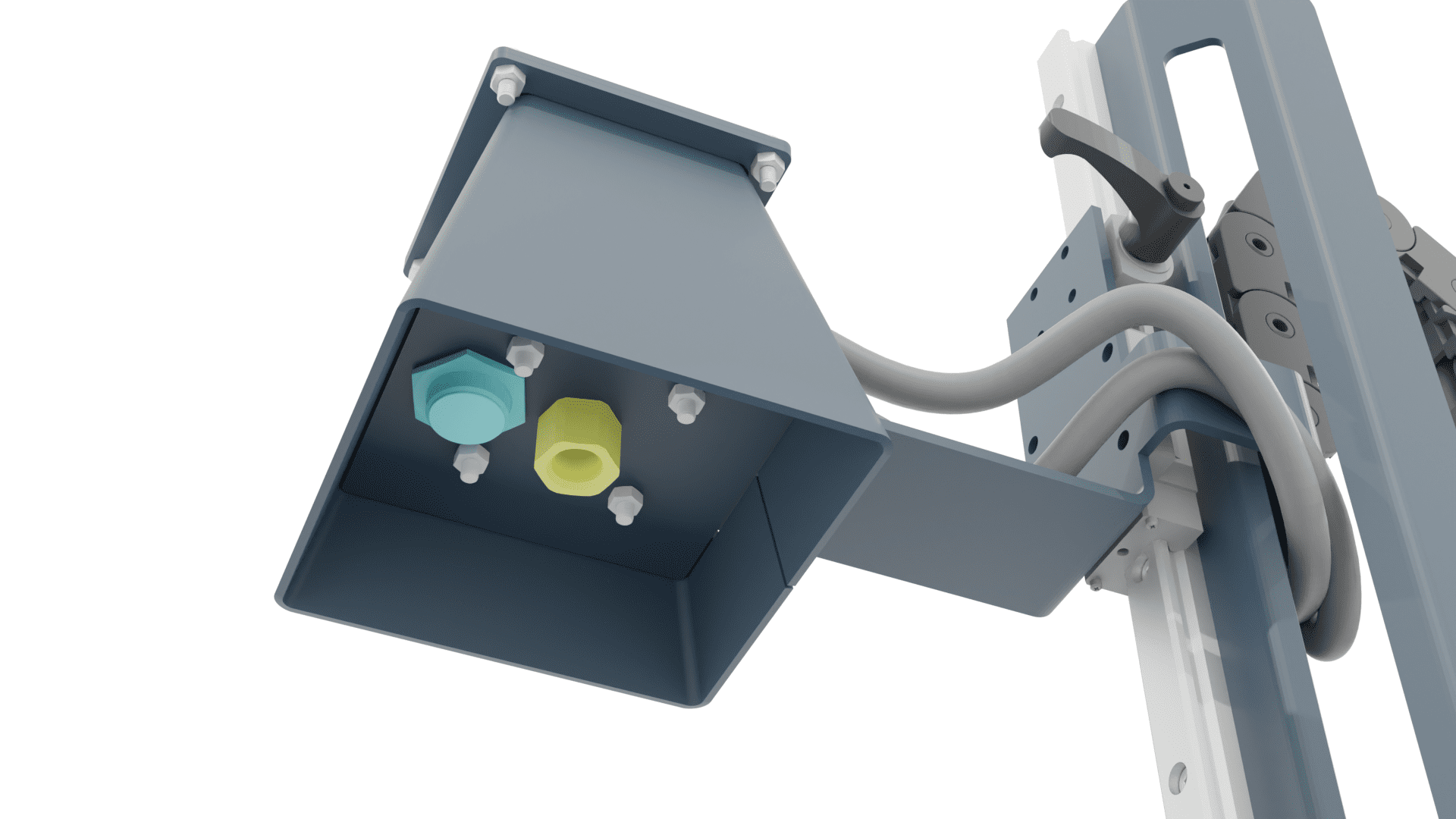

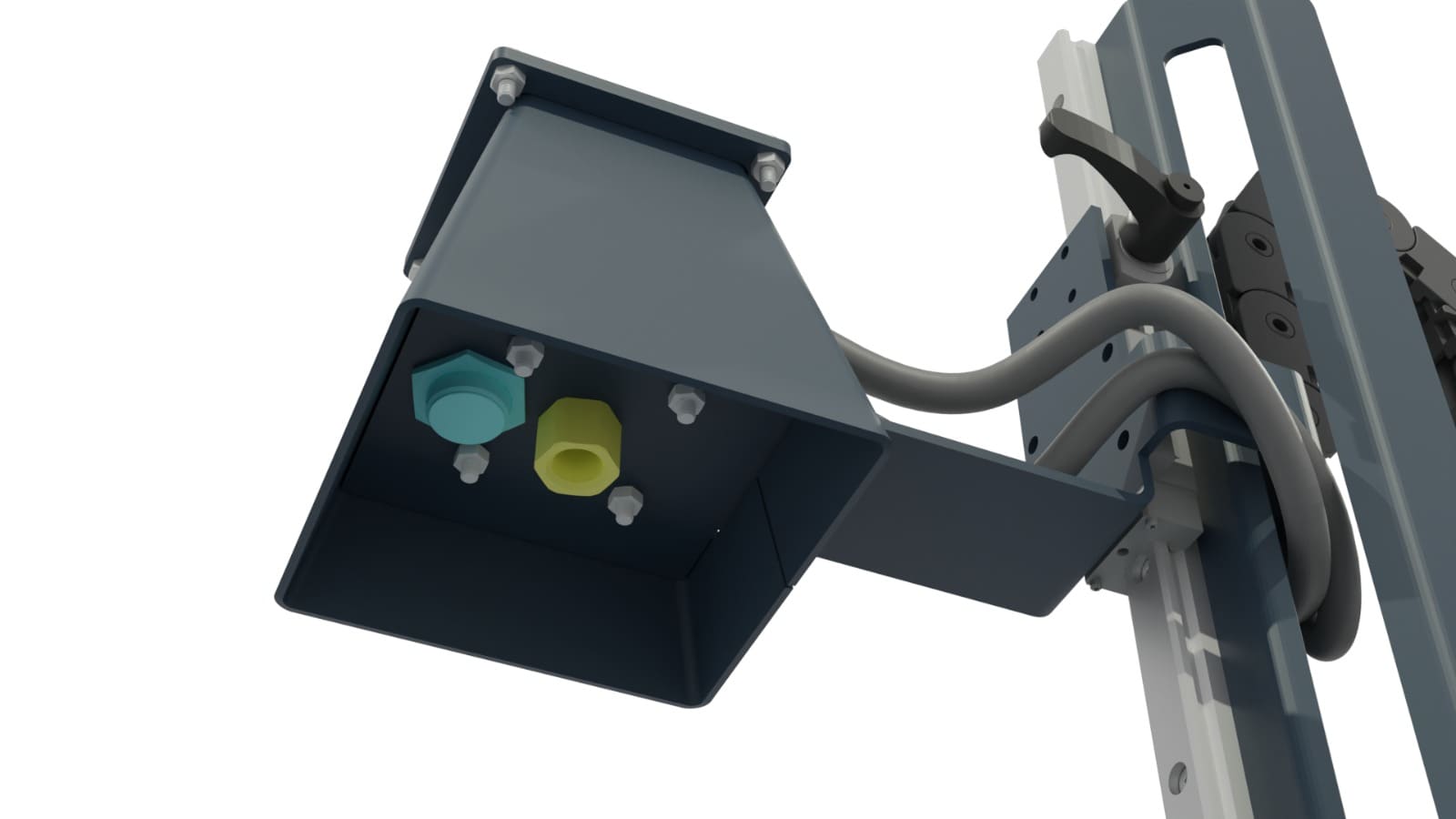

This type of equipment is often used in industrial applications such as the production of polyurethane foam. Polyurethane foam is formed as a result of a reaction by mixing components such as a polyol and an isocyanate. During this reaction, the foam material expands in volume and rises. A foam measurement tester helps the quality control process by accurately measuring the amount of this rise. The equipment usually contains a measuring cup or mold. The foam material is poured into this container and begins to rise when the reaction is initiated. The equipment uses different sensors or gauges to precisely measure the amount of rise. These sensors can detect the rate at which the foam rises, the volume change or the pressure change.

Foam measurement testers are used to ensure quality control during the production process, to ensure that the material components are mixed in the correct proportions and to determine that the foam exhibits the expected properties. These equipments can also evaluate the reaction speed or time of the foam material.

In general, foam measurement testers are important tools used to measure and control the volume changes that occur during the formation reaction of foam material. By using these devices, manufacturers can produce foam materials that meet quality standards and have the desired properties.

Technical Specifications

Measurement Principle | Optical or sensor-based |

Measurement Range | 0 – 100 mm (customizable) |

Sensitivity | ±0.1 mm |

Screening Unit | Millimeter (mm) |

Power Supply | AC 220V, 50Hz |

Measurement Standards

ASTM D3574, ISO 1798, ISO 3386-1, ASTM D3575, ASTM D1621, ISO 1798, ISO 3386-1, ASTM D3575, ASTM D1621 standards specify some of the measurement methods and testing procedures used in the measurement of foam materials. Our MK-1020 Foam Measurement Tester is designed with these standards in mind.

Areas of Use

Furniture Industry: Foam Measurement Tester is used to check the quality of foam materials used in the furniture manufacturing process. Accuracy of the amount of rise is an important factor affecting the comfort and durability of furniture pieces.

Automotive Industry: In the automotive industry, the Foam Measurement Tester is used to evaluate the quality and performance of foam materials such as vehicle seats, upholstery and interior trims. The amount of rise is an important parameter that affects the comfort level and seating position.

Mattress and Pillow Production: In the mattress and pillow industry, the Foam Measurement Tester is used to check the quality of foam materials that ensure sleep comfort. The amount of rise is an important factor determining the support and comfort levels of mattresses and pillows.

Packaging Industry: Foam materials are used in the production of packaging materials. The Foam Measurement Tester can be used to evaluate the protection properties and durability of packaging by measuring the amount of rise of these materials. Insulation Materials: Insulation materials used for heat and sound insulation are usually made of foam materials. The Foam Measurement Tester can be used to evaluate the insulation performance of these materials by measuring the amount of rise.

Insulation Materials: Insulation materials used for heat and sound insulation are usually made of foam materials. Foam Measurement Tester is used to evaluate the insulation performance of these materials by measuring the amount of rise.

Why VILUTRA?

For our customers, it is important to ensure quality control in the production of foam materials and to obtain precise measurement results. For this reason, we offer you the best service and advantages as our Foam Measurement Tester provider.

High Precision: Our Foam Measurement Testers have high levels of precision. Using sensitive sensors and measurement technologies, they measure the amount of uplift of foam materials extremely accurately. This is a huge advantage in ensuring the quality of your products and increasing customer satisfaction.

Flexibility and Customization: We have the ability to customize Foam Measurement Testers to meet customer needs. We can adjust measurement ranges, sampling capacities, speeds and other technical specifications according to your requirements. This way, we can offer an ideal solution to meet the specific requirements of your business.

User Friendly Interface: Our devices are equipped with user-friendly control panels. This makes them easy to use and allows your staff to adapt quickly. We also offer a user-friendly software interface so that data can be easily read and analyzed. Reliability and Durability: Our Foam Measurement Testers are designed for industrial use. They are made of quality materials and have a robust construction. This ensures a long-lasting and durable equipment.

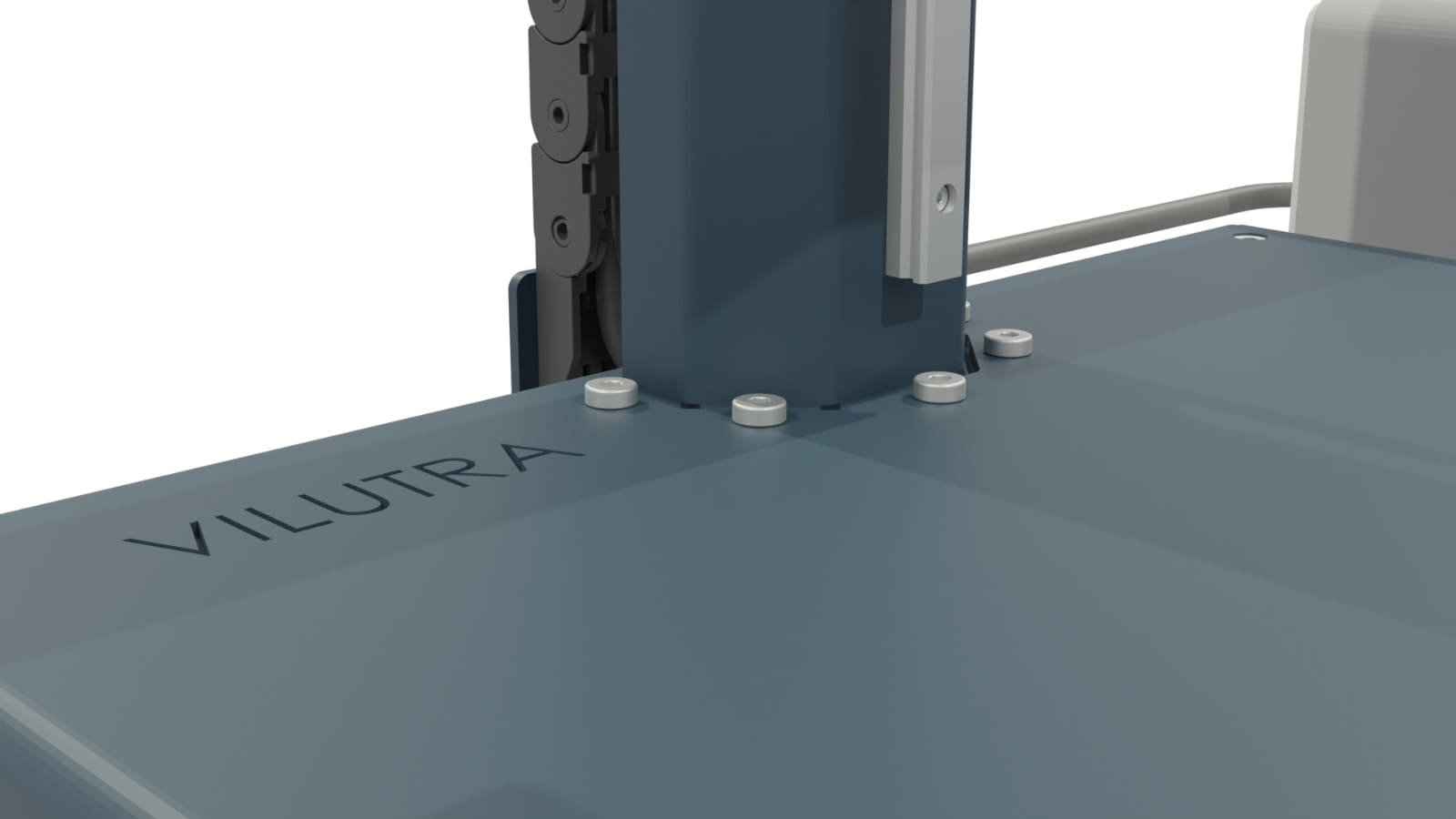

Reliability and Durability: Our Foam Measurement Testers are designed for industrial use. They are made of quality materials and have a robust construction. This ensures a long-lasting and durable equipment.