VILUTRA MK-1070 FOAM TENSILE TESTER MACHINES

What does it do?

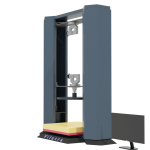

MK-1070 Foam Tensile Tester Machines, i.e. foam tension testers, are devices used to test the tensile strength of foam materials. They are widely used to determine the quality of foam materials and to measure the performance of materials used in the design process.

Foam materials are lightweight, flexible and generally low-density materials. Therefore, their strength and elongation properties play an important role in the design and manufacturing process. Foam Tensile Tester Machines can determine the performance of foam materials by measuring their tensile, rupture, tensile and compression properties.

They are high-precision machines capable of precise measurements. The test results can be used in product design and quality control, and since foam materials are used in many industries, these machines have a wide range of applications.

How to Use?

Foam Tensile Tester Machines can be used in different ways depending on their intended use. However, the following steps are usually followed:

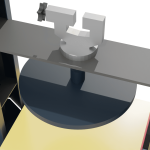

- Preparation: The foam sample specimens to be tested are brought to the appropriate shape and size. The sample is placed in the jaws or clamps of the machine.

- Determination of test parameters: Depending on the type of material to be tested and its purpose, the test parameters are determined. These parameters may include properties such as strain rate, tensile strength and breaking point.

- Performing the test: On the machine’s control panel, the test parameters are entered and the test is started. During the test, the machine applies a specific load to the specimen and measures the tensile behavior of the specimen. The test results are usually displayed on the computer screen or on the machine’s display.

- Data analysis: The test results are saved in a data file and then analyzed. The analysis results may include information such as the tensile behavior of the material, the breaking point, stress-strain graph, etc.

Complied Standards?

Materials testing machines such as Foam Tensile Tester Machines are designed and manufactured in accordance with industrial standards to ensure accurate and reliable measurement of the properties of the material under test. Industrial standards used in this machine may include the following:

- ASTM D3574: Standard Test Methods for Flexible Cellular Materials – Slab, Bonded, and Molded Urethane Foams

- ASTM D1621: Standard Test Method for Compressive Properties of Rigid Cellular Plastics

- ISO 844: Rubber and plastic testing equipment – Tensile, flexural and compression types (constant rate of traverse) – Specification

- EN ISO 178: Plastics – Determination of flexural properties

- EN 826: Thermal insulating products for building applications – Determination of compression behaviour

These standards define specific test methods and procedures to ensure that the properties of the material being tested are measured accurately and that the results are comparable between different laboratories.

Benefits Provided

Materials testing machines such as Foam Tensile Tester Machines are designed to accurately and reliably measure the properties of the materials under test and offer many advantages. Some of the advantages include:

- Precise measurement: The machine precisely measures many parameters such as stress, strain, load and force-displacement graph. These measurements are used to accurately measure the true properties of the material.

- High speed testing: The machine is capable of testing at high speeds. This allows the mechanical properties of a sample to be tested at different speeds.

- Flexibility: The machine is designed for testing different materials. This allows the machine to be used in different industries.

- Automatic data collection: The machine can automatically record and analyze measured data. This enables test results to be obtained faster and more accurately.

- High efficiency: The machine works faster and more efficiently than methods where tests are performed manually. This can speed up laboratories’ testing process and reduce operating costs.

- Safety: The machine has automatic stop features for overloads and other hazards during testing. This ensures the safety of users.

These advantages show why materials testing machines such as Foam Tensile Tester Machines are widely used in industrial applications.

Areas of Use

Foam Tensile Tester Machines can be used for materials testing in many industries. Some examples are:

- Automotive industry: Used for testing materials used for cars, trucks, motorcycles and other vehicles (e.g. seat cushions, door panels, steering wheel covers, console covers, etc.).

- Furniture industry: Used for testing foam (especially seat cushions) used for furniture, mattresses, upholstery fabrics and other household items.

- Packaging industry: Used for testing packaging materials (e.g. foam and bubble wrap) for food, pharmaceuticals, cosmetics and other products.

- Construction industry: Used for testing thermal insulation materials (e.g. foam, polystyrene, mineral wool, etc.).

- Electronics industry: Used for testing materials used for electronic devices (e.g. keyboard pads, mouse pads, headphone pads, cell phone cases, etc.).

- Medical industry: Used for testing materials used for medical devices (e.g. surgical masks, gloves, medical foams, etc.).

Materials testing machines such as Foam Tensile Tester Machines are an important tool for conducting materials testing in different areas of the industry and provide accurate and reliable results.